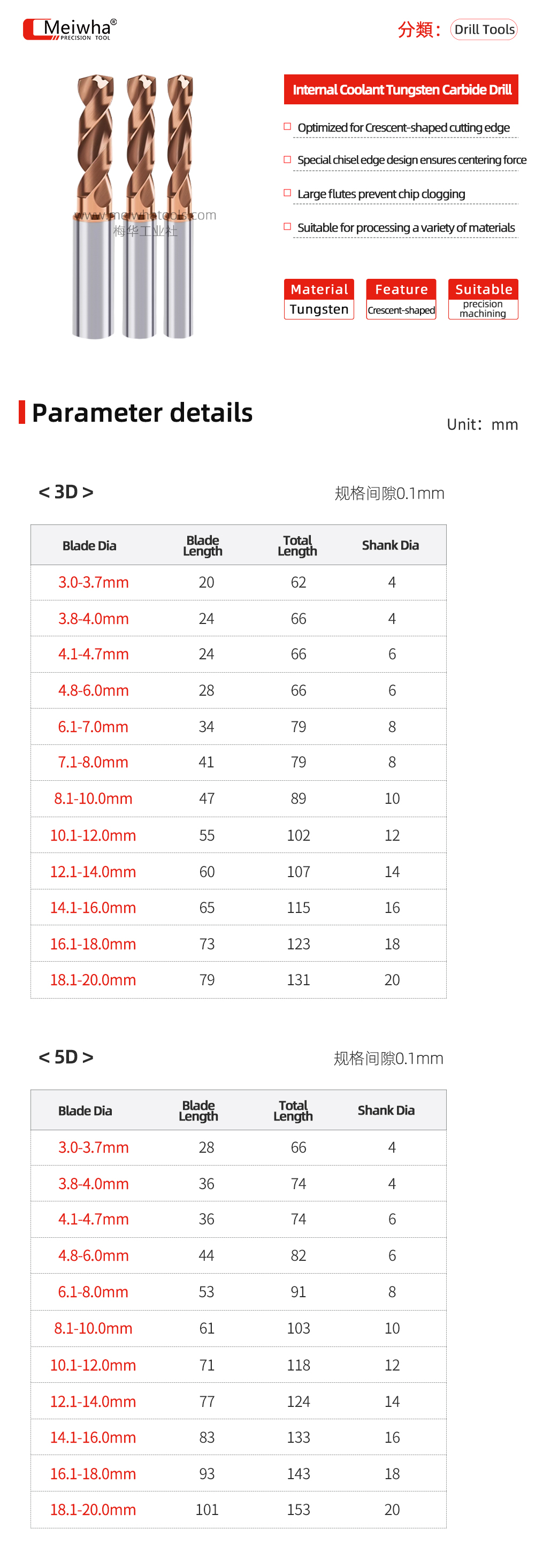

Internal Coolant Tungsten Carbide Drill

Internal Coolant Tungsten Carbide Drill with Center Coolant Outlet

Features center coolant outlets for direct cooling during high-speed machining, reducing cutting zone temperatures by 40-60% and extending tool life.

Effectively flushes chips and suppresses built-up edge (BUE), especially suitable for deep-hole drilling (depth-to-diameter ratio ≥5×D).

Widely used in aerospace, mold manufacturing, medical devices, and other precision industries.

Key Features:

Specialized for Stainless Steel/Titanium Alloy/High-Temperature Alloys:

Optimized geometry and coatings for challenging materials.

Dual Center Coolant Outlets:

Rapid cooling enhances drilling stability and precision.

Parabolic Flute Design:

Significantly improves chip evacuation, preventing clogging.

Advanced Coating Technology:

High surface finish and durability, suitable for high-speed operations.

ch

ch English

English